The beginning of the development of the Chateaugay Ore and Iron

Company is closely

connected with the early iron industry, which was of con-

siderable importance

to northern New York during most of the Nineteenth

Century, and

especially to Clinton and Essex counties which, 54 years ago,

produced 23 per cent

of the total iron ore output of the United States.

From 1798, when Platt erected the first forge on the Saranac River at

Plattsburg, N. Y.,

the iron business took on impetus. Year after year new ore

deposits were

discovered and ironworks started. The Saranac River, due to

its many rapids and

falls, lent itself very profitably as a source of power in

many places.

Its proximity to abundance of charcoaling timber and to numer-

ous ore beds made it

ideal for ironworks locations, of which several operated

successfully for many

years. Thus, this section of northern New York was

destined to become

a large and important part of the American Bloomery.

Closely associated with this industry were two men, Andrew Williams

and Smith M. Weed,

the founders of the Chateaugay Ore and Iron Company,

and this narrative

would not be complete without making brief mention of some

of the activities of

these two gentlemen.

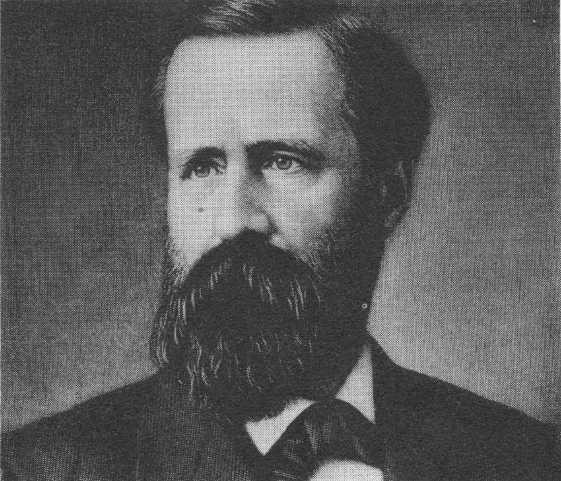

Andrew Williams

Andrew Williams, when a young man, began work at one of the

Catalan forges on the

Saranac River. Having a good common school education

to begin with, he

applied himself diligently year after year until he became one

of the best informed

and most able men in the industry, always endeavoring to

improve the quality of

his iron, continually prospecting and seeking purer and

better ore deposits.

Several years before the opening of the Chateaugay Ore Beds, it is said

that Mr. Williams had

secured samples of this ore, packed it many miles through

the forests to his

forge on the Saranac River, and made up special samples of

iron from it, which

were properly ear-marked as they went to the trade, the

customer being

requested to report back as to the quality. The splendid reports

received from various

customers in the trade on the samples of iron made from the

Chateaugay ore and

the many requests for more of it, caused Mr. Williams to

become very much

interested in the opening and development of the Chateaugay

Ore Bed, despite its

inaccessibility. It may be that he thought along the lines

of Emerson's

Mousetrap Story.* * * In any event, he associated himself with

Smith M. Weed

and, despite the many natural obstacles, undertook to open up

this ore and

make a better iron, and did so.

Smith M. Weed graduated from the Law School at Harvard

University

in 1857, and in 1859 he married Carrie L. Standish, a daughter of

Colonel

Matthew M. Standish, a lineal descendant of Colonel Miles Standish, of

Ply-

mouth. Standish, N. Y., where the Company's blast furnace is

located, was

named for Mrs. Weed's family.

Mr. Weed, in addition to being an able lawyer, was a statesman of first

rank. He was elected and re-elected many times to the State

Assembly, and

made and retained the friendship and confidence of Governors and

Presidents.

Mr. Weed, more than any other one man, was responsible for interesting

the Delaware and Hudson Canal Company's officers in the building of a

railroad

between Whitehall and Plattsburg. The history of The Delaware and

Hudson

Company, "A Century of Progress," says of Mr. Weed:

Early in 1872 he journeyed to New York in the effort to interest the

Delaware and Hudson Canal Company. At a meeting with some of its

officers

and Managers, at which I. V. Baker who shared his aspirations was

present,

Mr. Weed readily convinced George Talbot Olyphant, acting as president

in the

absence of Mr. Dickson, LeGrand B. Cannon and others that such a line

would

be of great advantage to the company. Thereupon Mr. Weed drew

from his

pocket articles of association of The New York & Canada Railroad

Company,

already signed by several residents of Plattsburg and Clinton

County. The

remaining signatures necessary to effect its incorporation were quickly

supplied."

In later years, the two gentlemen who successfully founded and com-

mercially developed the Chateaugay Ore and Iron Company were known as

Honorable Andrew Williams and Honorable Smith M. Weed, both having won

distinction in State activities, as well as in the industrial

enterprise in which they

were interested; one a master of the industrial arts, and the other a

master in the

art of statesmanship; both of noble character.

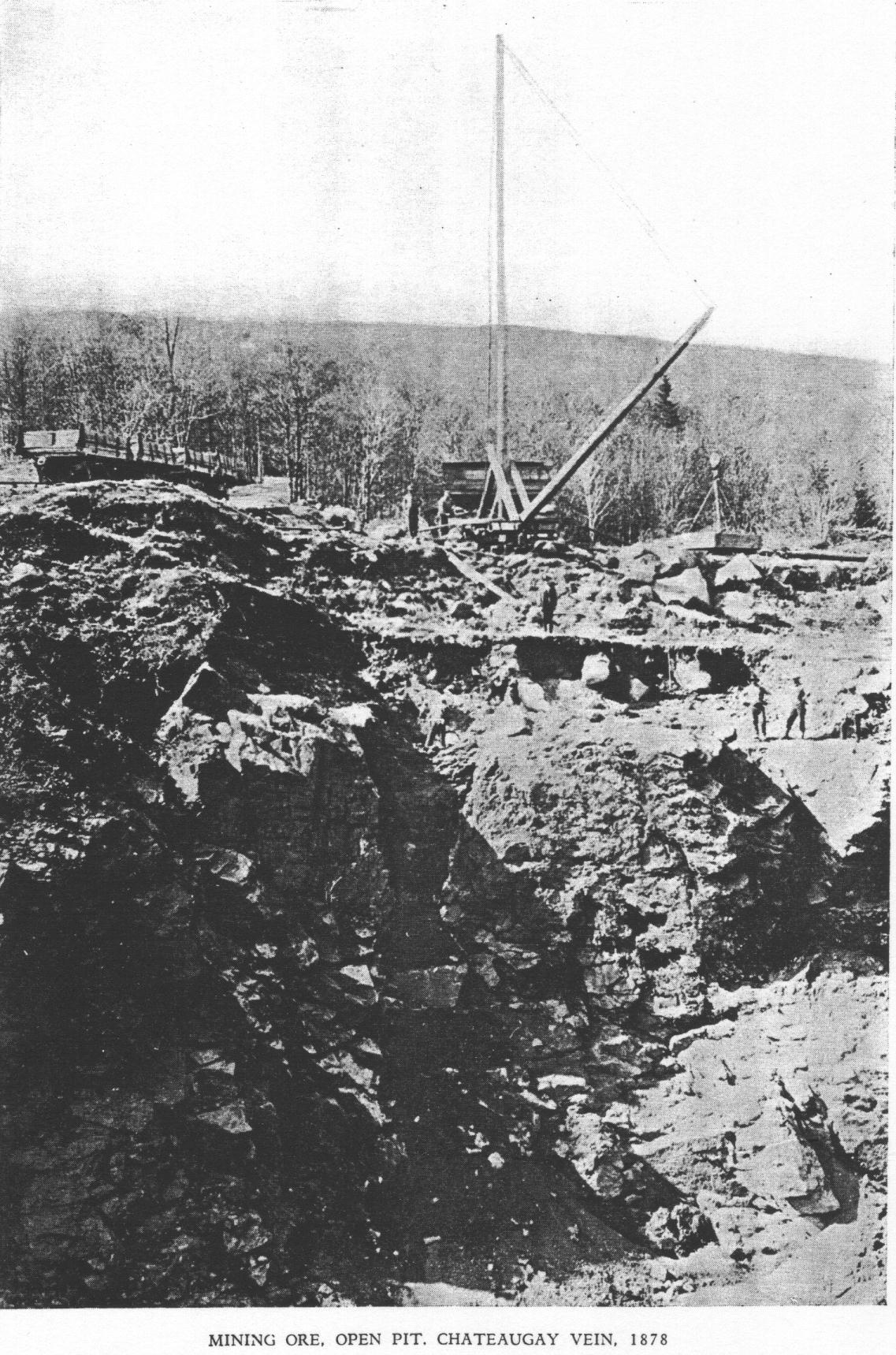

pit1878.jpg = fullsize

In 1781, the Legislature of New York set apart, in the north central

part of the state, a tract of land containing about 665,000 acres,

lying in Clin-

ton, Franklin and Essex counties, to satisfy the claims of two

regiments of

soldiers which the State of New York had found it necessary to raise to

protect

its frontier settlements from frequent pillage by the Indians and other

enemies.

Congress was too poor to furnish troops for their protection, and so

the State

sought to raise them and pay for their services in the manner above

mentioned.

This land is the so-called Old Military Tract.

* * * Many are inclined to credit Elbert Hubbard with the

Mousetrap Story. Sarah Yule, in a

book called 'Borrowings," printed many years before the Roycrofters,

credits Emerson as being

the author of the quotation.

Due to failure of the act to express clearly its meaning, and because

of its

vagueness, another act was passed in 1786, defining the area to be

surveyed, and

allowing the speedy sale of these and other unappropriated lands within

the

state. However, no part of the Old Military Tract was ever

awarded on

bounty claims. It was ultimately all sold by the State as "wild

lands." The

Town of Dannemora, in which the Chateaugay Ore Bed is located, lies in

Township No.5 of this Old Military Tract.

In September, 1794, Township No.5 became the property of William

Henderson, merchant, of New York City, who sold it in January, 1795, to

Jacob Mark. In February of the same year, Mark mortgaged it to

Jacob and

Robert Leroy, and from that time on, for about a quarter of a century,

it being

considered of little value, the property changed hands a number of

times.

In 1822, it was owned by John L. Norton and Hannah Murray, who divided

it up into 300 lots which lay in what was afterwards incorporated into

the

towns of Ellenburg and Dannemora. In the apportionment of the 300

lots

between the owners, the part which lay in Dannemora fell to Hannah

Murray,

who in turn conveyed it, on November 22, 1822, to Lloyd N. Rogers.

There is good reason for believing that the discovery of iron ore in

the

north central portion of this tract was made many years before.

Several miles

westward of the Chateaugay Mine, and on the same strike as the

Chateaugay

Ore Bed, is an old opening (81 mine), which had evidently been

worked to a

considerable extent at some remote period, a shaft having been sunk,

from which

quantities of waste which present day manufacturers would call good ore

had

been thrown out and left. Trees of considerable size had grown

over some of

this waste pile. It is reasonable to suppose that this is the

so-called Prall vein,

from which William Bailey, who erected a forge on the Chateaugay River

about five miles below the outlet of Chateaugay Lake, in 1803, obtained

his ore,

shipping it on rafts or boats through the Upper and Lower Chateaugay

lakes

to his forge.

However, there does not seem to be any record of the actual discovery

of the Chateaugay Ore Bed up to the time of Mr. Rogers' purchase.

In the year

1823 the bed of ore, practically phosphorus free, now known as

"Chateaugay,"

and which has been proven to be the best in the world, was supposed to

have

been discovered by an old trapper named Collins.

But the Ore Bed lay in the depths of what was then considered an almost

impenetrable wilderness, and it was many years before any attempt was

made

to work it. Even after it was known, it excited little interest

among capitalists,

for the reason that it was so far from lines of transportation, and

lying in a

region which abounded in natural obstacles, held to be practically

insurmount-

able against the building of roads of any kind.

It was not until about 1868 that the first steps were taken toward

utilizing this treasure, when Messrs. Foote, Weed, Meade and Waldo made

a

contract with Edmund Law Rogers, of Baltimore, son of Lloyd N. Rogers,

and

soon after obtained possession of the property.

However, for a period of about five years there was very little done in

the way of development

of this ore body. Small groups of men were engaged

during the summer

months in digging the ore, piling it on the surface to be

loaded during the

winter months and hauled by horse-drawn sleighs on the

snow through the dense

wilderness to the Catalan forges on the Saranac River.

The interest of the above named group was soon transferred to the

Chateaugay Iron

Company, organized by Smith M. Weed and Andrew

Williams, and in the

fall of 1873, the work of developing the property began in

earnest. A plank

road was built from the Saranac River Plank Road, branch-

ing from that road

at Saranac Hollow, and running 13 miles through the

mountains to the Ore

Bed.

The jigging baskets consisted of a screen in the shape of a cylinder

open

at the top, with a

bail to which was attached a piece of wooden timber acting

as a fulcrum or

lever. The ore was shoveled into the basket, which was then

lowered into a tank of

water and "jigged" up and down. The ore, being

heavier, sank to the

bottom of the basket, while the rock impurities formed a

layer on the top,

which was scraped off and sent to the waste pile.

The operation was continuous 24 hours daily, except Sunday, producing

approximately ten

gross tons of concentrated iron ore, containing about 55 per

cent iron. The

loss of iron in the tailings, however, was enormous. The

concentrated ore was

then loaded into wagons, which held approximately two

tons, and transported

over the plank road to Russia, N. Y., where it was made

into blooms in the

six-fire forge owned by Andrew Williams and C. F. Norton.

In the subsequent years, the property was opened up considerably. The

mines were sunk

deeper, necessitating larger hoisting equipment and also the

introduction of

pumping machinery to take care of water drainage. Up until

this time, all of the

drilling was done by hand, using jumpers and hammers,

two men drilling on

the average twelve lineal feet per shift. With the in-

troduction of

compressed air driven drilling machines, the drilling and the

tonnage per man per

day was substantially increased. A steam sawmill was

built and kept in

constant operation, turning out lumber for new buildings,

plank roads,

etc. An addition was made to the separator to take care of the

increased output of

the mines. Additional miners and mill hands were brought

in, until the total

number of employed reached about 150. This, of course,

meant that new houses

had to be built, and at this time we find about 40 houses,

a school house and

church composing the village of Lyon Mountain.

A small dam on Separator Brook, which comes brawling down from

Mount Lyon, secured a

head of 48 feet, which was suflicient to run the separator

a good portion of the

year, and a 30 horse power steam engine supplied whatever

force was lacking for

either the separator or sawmill. The Chateaugay Ore and

Iron Company now owned

over 35,000 acres of land in this immediate region,

a great portion of

which was covered with heavy timber, well adapted to lum-

bering and charcoaling

purposes. They also had a 40-year lease on 4,000

-additional acres on

which the Ore Bed was located, and with the privilege of

cutting every tree

which grew upon it. Thus, it will be seen that they had

control of nearly

40,000 acres of land, with a large supply of iron ore under it

and plenty of

charcoaling timber on its surface.

With the increasing of men and machinery the output of concentrated

ore reached

approximately 50 gross tons per day, containing about 55 per cent

iron. This was

loaded into wagons and hauled over a splendid plank road to

the dock on Upper

Chateaugay Lake. Here it was transferred into barges,

which were towed to

the Company's forge fires at Belmont, at the outlet of

Lower Chateaugay Lake,

by the Company's steamer, "Maggie," named after

Miss Maggie Weed

(daughter of Hon. Smith M. Weed).

The "Maggie" was 28 1/2 feet long over all, with an 11 foot beam,

drawing four feet of

water. It was driven at the rate of ten miles per hour, by

a 25 horse power steam

engine. The barge, the "Iron Age," was 80 feet long

and 17 feet wide, and

carried approximately 150 tons of ore. After the ore

was transported to

its destination, it was transferred by hand to a small car

which was drawn by

a cable to the stock piles at the forges.

At the outlet of Chateaugay Lake, at Belmont, ground was broken for

the erection of a dam

and ironworks, in the year 1874, and operations began

in January of the

following year. The entire operations were driven by

water power under a

head of 18 feet. The "mill pond" was 12 miles long,

both Upper and Lower

Chateaugay Lakes having been raised by the dam about

4 1/2 feet. All

the wood, coal and ore were moved on the Lake in barges and

rafts by the "Maggie."

Each Fall before the close of navigation, enough ore was

stored at Belmont to

run the forges through the Winter. There were ten first-

class fires, which

were increased in later years to 20, the largest Catalan forge in

operation in the

country, if not in the world, at that time.

Go to Mine History Page 2 ........

![]()