The blooms and billets were hauled by wagons and sleighs to Chateau-

gay, N.Y., and shipped

via the Ogdensburg & Lake Champlain Railroad to the

steel districts of Pennsylvania

and Ohio. There is no doubt but that the

same inherent qualities

of the Chateaugay iron, which are in demand by the steel

men of today for their

toughest projects, were known and appreciated during this

period. The records

at this time indicate a large tonnage of Chateaugay blooms

being made for shipment

to the wire manufacturers for the Brooklyn Bridge.

The Catalan forge furnace, in which iron was made direct from ore, was

an open hearth, about

2 1/2 feet by 3 1/2 feet, with a stack 20 feet to 25 feet high

for carrying off the

gases.

The blast of air was usually furnished either by a bellows, or by means

of a trompe. The

pipe thai carried the air to the hearth was coiled in the

stack of the furnace,

the object being to preheat the blast of air, which resulted

in a saving of fuel.

The operation consisted of a charcoal fire, stimulated by a blast of air,

iron ore and charcoal

in small quantities being added alternately by the blooms-

man, who also regulated

and adjusted the fire, until the batch of iron, called a

"loupe," weighing about

300 pounds, was made. This usually took about

three hours.

The "loupe," in a pasty state, mixed with slag, was loosened in the

hearth by means of bars,

and then lifted from the furnace with tongs, known as

"grampuses," promptly

taken to the trip hammer and forged into blooms or

billets, a bar of iron

about 5 inches square, varying in lengths from two to

six feet, depending upon

the market demands.

The iron made was exceptionally pure. The following is an analysis

made recently in the

Company's laboratory of one of the old Chateaugay blooms

which has been preserved:

Iron

99.70 %

Silicon ..

.08

Sulphur

.017

Phosphorus

.017

Combined Carbon

.130

Manganese

Nil

The Company at this time was fairly prosperous. The following was

told of the late Hon.

John Moffitt, who for a number of years was President

of the Plattsburg National

Bank & Trust Company:

"It seems that in the early ' 70's Mr. Moffitt was General Manager

of the Chateaugay Company's operations. His responsibilities as Man-

ager included the purchase of the Company's supplies, the payment of

bills, the sale of products, and the collection of all money due the Com-

pany. Shortly after the close of one successful year, the Company

having manufactured and sold some 4,000 tons of iron, the late Hon.

Smith M. Weed, President of the Company, asked Mr. Moffitt how

much money the Company made during the past year. The reply

represented a very substantial profit. Mr. Weed promptly said that

he

had been to see the bookkeeper, and was quite sure that the books did

not show net earnings anywhere near this amount. Mr. Moffitt

promptly replied that he did not care what the books showed. He had

paid all of his bills and had that much money left in the bank."

This early period of development, however, was accompanied by a great

deal of hardship for

both the management and the employees. The winters

were cold, with heavy

snows, making it very difficult at times to obtain food

and clothing. Wild

meat, in the form of venison, rabbits, birds and fish, was

quite plentiful and,

had it not been for this, there would have been a great deal

more suffering than there

was. Flour, one of the necessities of these hard labor-

ing pioneers, was lacking

for months at a time, and was obtained, when possible,

at a premium.

Late in the '70s, the Company realized that in order to develop proper-

ly the rich resources

of its property to the best advantage, it must secure rail-

road communication with

the great iron markets of the country. The ques-

tion was, which way should

it strike out from the mine, lying in the very

heart of the wilderness.

Two routes were open to it: One down the

Chateaugay valley to

Chateaugay, N. Y., connecting with the Ogdensburg and

Lake Champlain Railroad,

and the other to Dannemora, to connect with the

Plattsburg & Dannemora

line. In February, 1879, when the snow was four

feet deep in the woods,

the work of making a preliminary survey was com-

menced, and early in

the spring the following data were at hand: Distance to

Chateaugay, 17 miles,

an almost straight line, with an easy grade all the way,

and the line running

nearly half way through the Company's own land, past

its Catalan forge at

Belmont, and the other half through a fine farming coun-

try, from which considerable

local traffic would be derived. Distance to Danne-

mora, 17 miles, ten of

which lay through solid wilderness, a crooked line

running around two mountains

and alternately toward all points of the com-

pass; a hard line to

grade, with the promise of little local traffic. Everything

seemed to indicate the

selection of the Chateaugay route as the most natural,

cheapest and best.

However, Thomas Dickson, President of the Delaware and Hudson

Canal Company, a close

friend of Smith M. Weed, concluded that the proper

movement of this ore

was to Plattsburg, then via the New York and Can-

ada Railroad. On

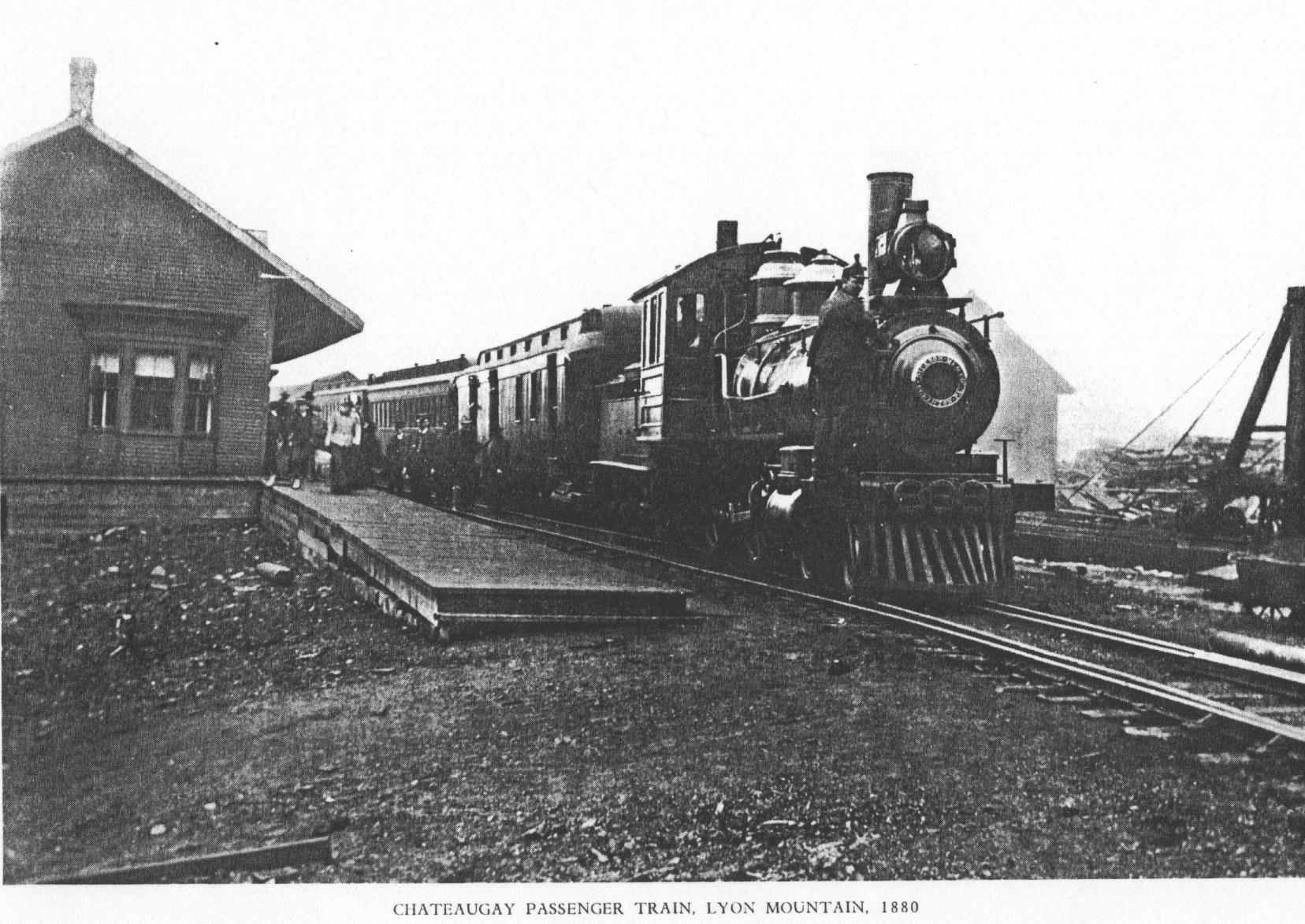

the 20th of May, 1879, the Chateaugay Railroad was

organized, with Thomas

Dickson as its President. Subsequently, the lease of

the Plattsburg and Dannemora

Railroad was secured from the State, and about

the 5th of June the contract

was let for grading of the Chateaugay Railroad

from Dannemora to the

Ore Bed. On the 8th of June the work began, and on

December 6th the track

laying was finished to the first shaft. On the 17th of

December, the first regular

train ran over the entire line, and on December 18,

1879, the first train

of ore was moved to Plattsburg.

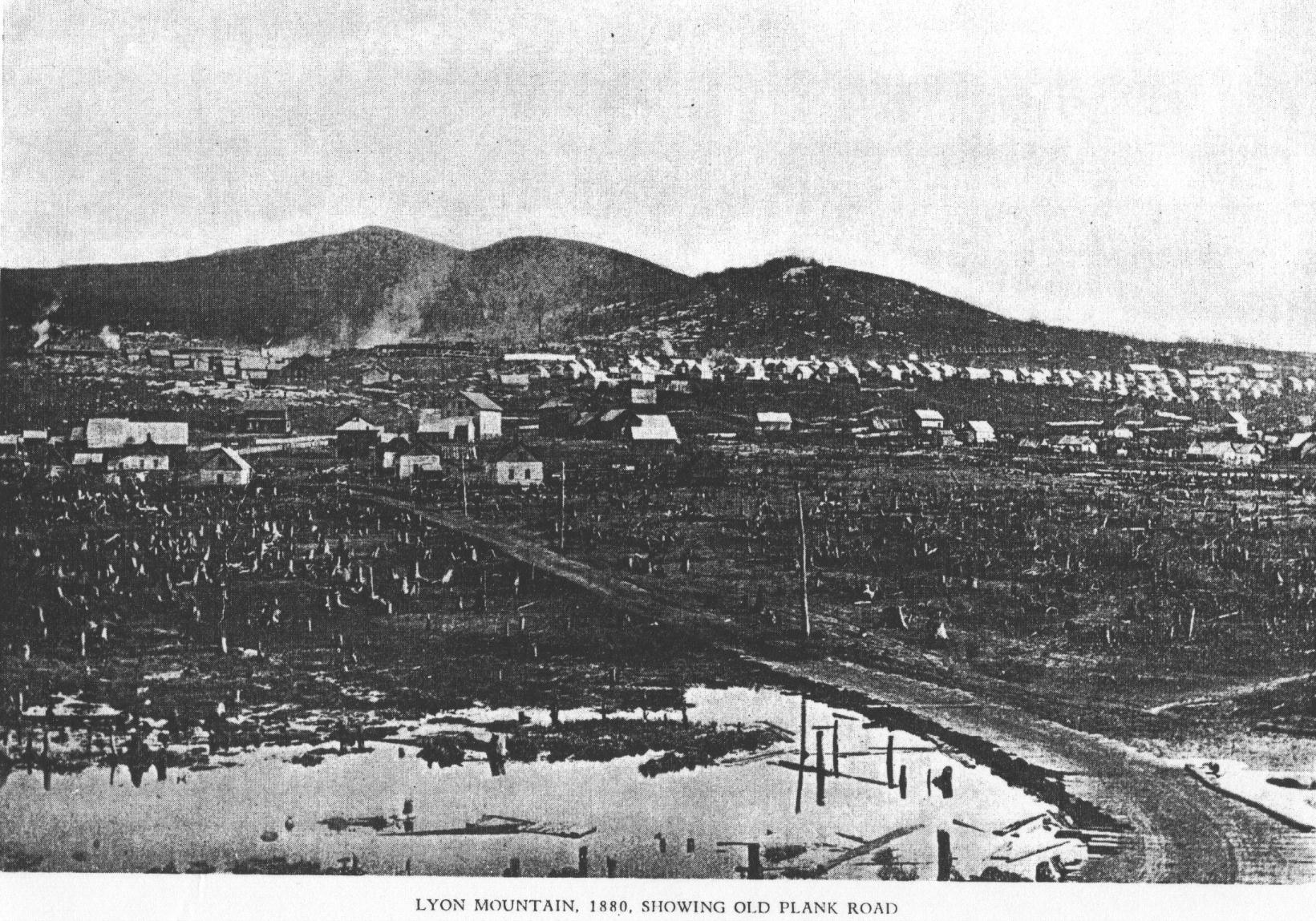

lmrr1880.jpg = fullsize

In the subsequent years, the operations at Lyon Mountain spread out

and increased at a rapid

rate. Directly above the "Old Opening" shaft, where

the first blow was struck

toward developing the Chateaugay Ore Bed in 1867,

and continuing southwest

along the strike of the vein, the Williams Opening

shaft had been sunk to

a depth of approximately 200 feet. Between the shafts

was an engine house,

36 x 52 feet, housing a compressor for air drills, and

pumping and hoisting

apparatus for both shafts.

Farther along was the railroad station, a building which now contains

the offices of the present

Company, and directly across the tracks a building

40 x 50 feet, with two

stalls for housing locomotives, had been erected. Adjoining

this was the machine

shop, 36 x 65 feet, with a second story for a carpenter

shop. This department

contained the most up-to-date iron lathes, planers,

drills, and other tools

needed to repair or rebuild engines or machinery, or to do

car repair work.

On the east bank of Separator Brook, an engine house 40 x 50 feet,

housing a 200 horse power

engine, designed to drive the separator, tools in the

machine shop, and hoisting

apparatus, was erected. On the opposite side of the

brook was No.2 Separator,

40 x 60 feet. Above, on the slope, were the roast-

ing kilns, alongside

of which was a side track from which ore from all shafts, to

be separated, was dumped

directly into the kilns, and thence worked down to

the ground floor of the

building, which was furnished with a Blake jaw crusher

and a revolving Conkling

separator. A short distance above was a substantial

dam. Cars were

loaded direct from the separator and hoisted by an engine on

an elevated track to

the main track.

At this time the vein was uncovered for about 1,500 feet. Shafts

had

been sunk at numerous

locations west of No.2 Separator and were equipped

with up-to-date steam

hoisting apparatus, steam pumps, and steam-driven com-

pressors for the air

drills. The average width of the vein was 20 to 25 feet,

the depth unknown.

Go to Mine History Page 3 .........

![]()